310°C

CURIE TEMPERATURE

Modern production

under strict quality control

State-of-the-art processing

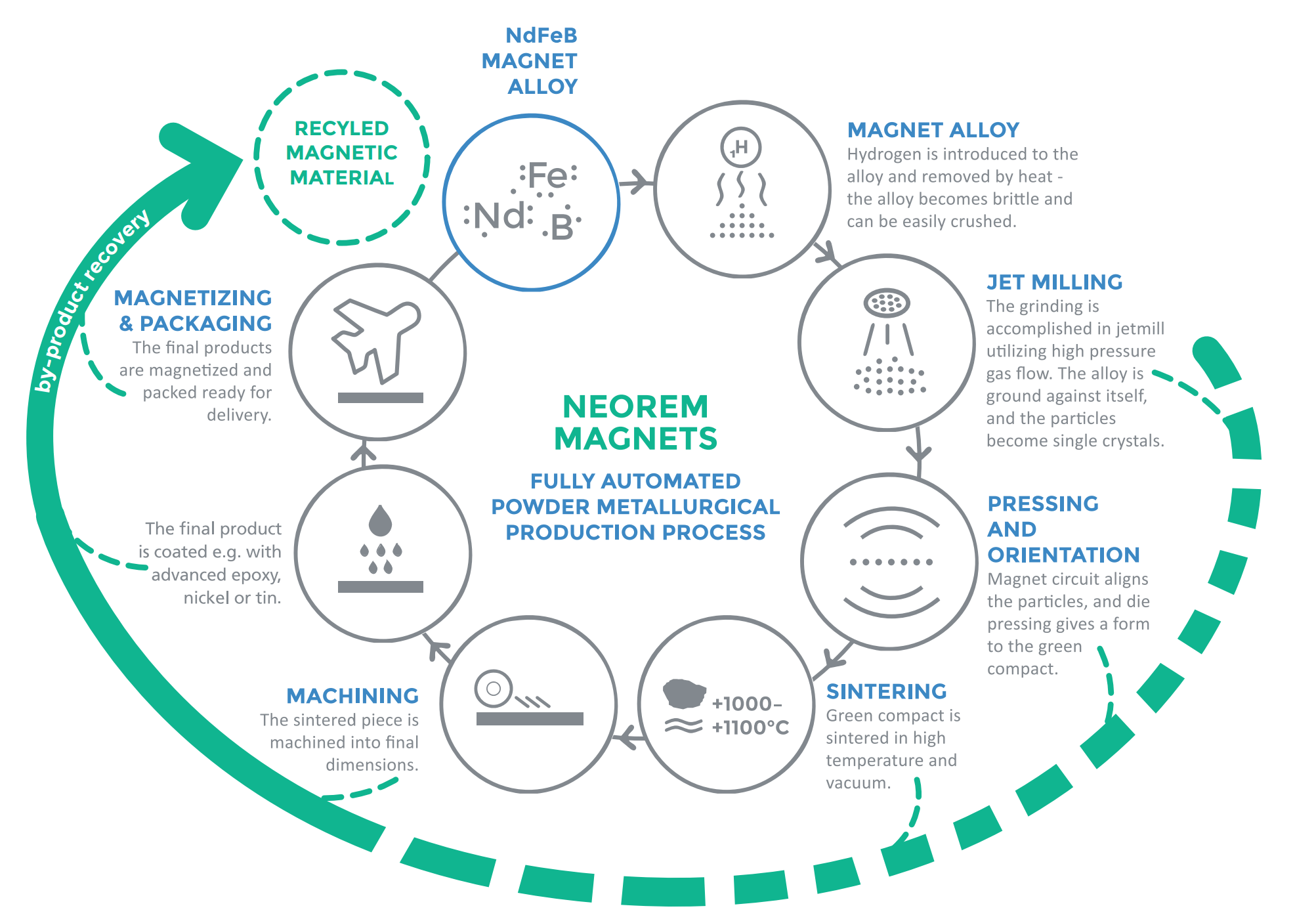

Neorem Magnets produces NdFeB permanent magnets in a modern, automated factory in Ulvila, Finland. Our magnets are produced powder-metallurgically by die pressing and sintering.

About the process

The process starts from the hydrogen decrepitation and jet milling of the magnet alloy. The resulting powder is then compressed into the desired shape, and at the same time its particles are aligned using a magnetic field. The compacted blocks are then sintered and machined into the final dimensions before coating and magnetizing.

Perfected touch

Quality inspection at each manufacturing step – together with strictly quality controlled production – provides a stable and well-controlled process, high yield, and homogenous and consistent magnet properties.

Powder metallurgical production process in Neorem Magnets

Our magnets are produced powder-metallurgically by die pressing and sintering. The process starts from the hydrogen decrepitation and jet milling of the magnetic alloy.

For more information refer to:

Permanent magnets

Magnet assemblies

Neorem’s expertise